Have you ever heard of the term "planned obsolescence?" If you haven't, it's the concept that since companies exist to make a profit, it's not in their best interest to make products that last forever. Instead, they last a few years and then things start to fail. Pieces break, electronics fail, springs fail, etc. In many cases, it's a simple matter of replacing a part, but of it had been built to last you wouldn't have to buy a replacement part.

I ran into this exact problem with our Dyson vacuum. We bought it because it's very lightweight, yet powerful enough to handle the majority of our vacuuming needs. We've had it a couple of years and just recently my wife mentioned the canister no longer stays attached when you go to empty it. Normally, it stops at the end of the rail after sliding forward. You can slide it back and forth to use gravity and momentum to empty it.

(Source)

(Source)

The problem with the design is the plastic retaining tab at the front of the gray plastic rail. It stops the canister from sliding right off of the rail. With repeated use, this plastic tab weakens and eventually breaks off. To fix it, the company hopes you'll go online and pay anywhere from $15-50 to buy the replacement rail. Then, you have to remove a ridiculous number of screws to take the old rail off and put the new one on.

(Source: Amazon)

(Source: Amazon)

Forget that! I decided to tinker and MacGyver it!

(Source)

(Source)

If you're not familiar with MacGyver, here's a brief overview of what the show is about for context.

(Source)

(Source)

Rather than pay for a replacement that will fail again after a year or two, I marked the height where the canister tab would normally meet up with the plastic tab in front to catch it. I marked a spot on the rail and drilled a hole. Then, I measured the height where the tab needed to be. I found a spare machine screw in the garage, measure it, and cut it with a pair of bolt cutters. Then, I threaded the screw halfway into the hole, applied some Loctite to the threads, then fully seated the screw.

I tested it out and it worked! The canister stops a little earlier than before since the screw is further back. I did this on purpose, so I wouldn't risk the screw ripping through the plastic rail over time.

It took me about 30 minutes of work, and only involved random pieces I had on hand already. I'm not paying $15+ for another piece that will fail eventually. With ample material around the screw, this fix should last the rest of the life of the vacuum. Rather than pay money to fix things, all it takes is a little time, analysis and creativity to "MacGyver it!"

Buy DUO and stake to receive Hive dividends, tip others, have your posts curated, and grow Hive!

https://tribaldex.com/trade/DUO

https://hive-engine.com/trade/DUO

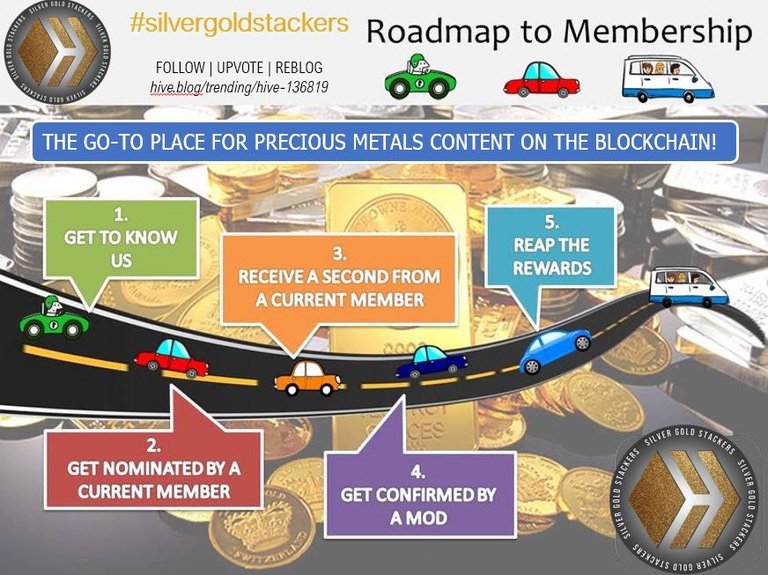

Do you like stacking gold and silver?

Are you new to Hive, or know someone new to Hive, and want help and support?

Have you been on Hive for a while and want to help new Hive members? Join HOC and help us grow Hive and encourage new members!